Autonomous mining vehicles could help yield 20% more lithium

As the electric vehicle (EV) transition gathers pace—from 5% of all new car sales in 2020 to 14% in 2022, according to the International Energy Agency—so too does the lithium market. Data from Statista suggests that 130,000 tons of lithium were mined in 2022, a 363% increase on the 28,100 tons mined in 2010. Fortune Business Insights projects that the global lithium mining market’s value will reach US$516.22m by 2028, up from US$343.22m in 2021—a CAGR of 6%.

Mining companies need to find a way to accommodate this surge in demand. Autonomous heavy equipment company SafeAI believes it can enable mining companies to do more and faster by retrofitting mining vehicles with the hardware and software they need to become fully autonomous.

Over the last ten years, 1,200 autonomous vehicles (AVs) have been deployed in mining projects, with eight billion tons of material moved autonomously, quickly and efficiently, without any fatal accidents.Bibhrajit Halder Founder and Chief Executive of SafeAI

He considers AV technology the surest way to optimise future lithium extraction.

The retrofit

“I was at Caterpillar Inc. for seven years and saw the humble beginning of AVs in heavy industry,” says Halder. “Later, while working at Apple, I saw how quickly self-driving technology was advancing. At SafeAI we’re taking those improvements back to the industry in which I started.”

Autonomous mining vehicles run continuously, yielding more material and keeping human operators out of harm’s way.

Autonomous mining vehicles run continuously, yielding more material and keeping human operators out of harm’s way.

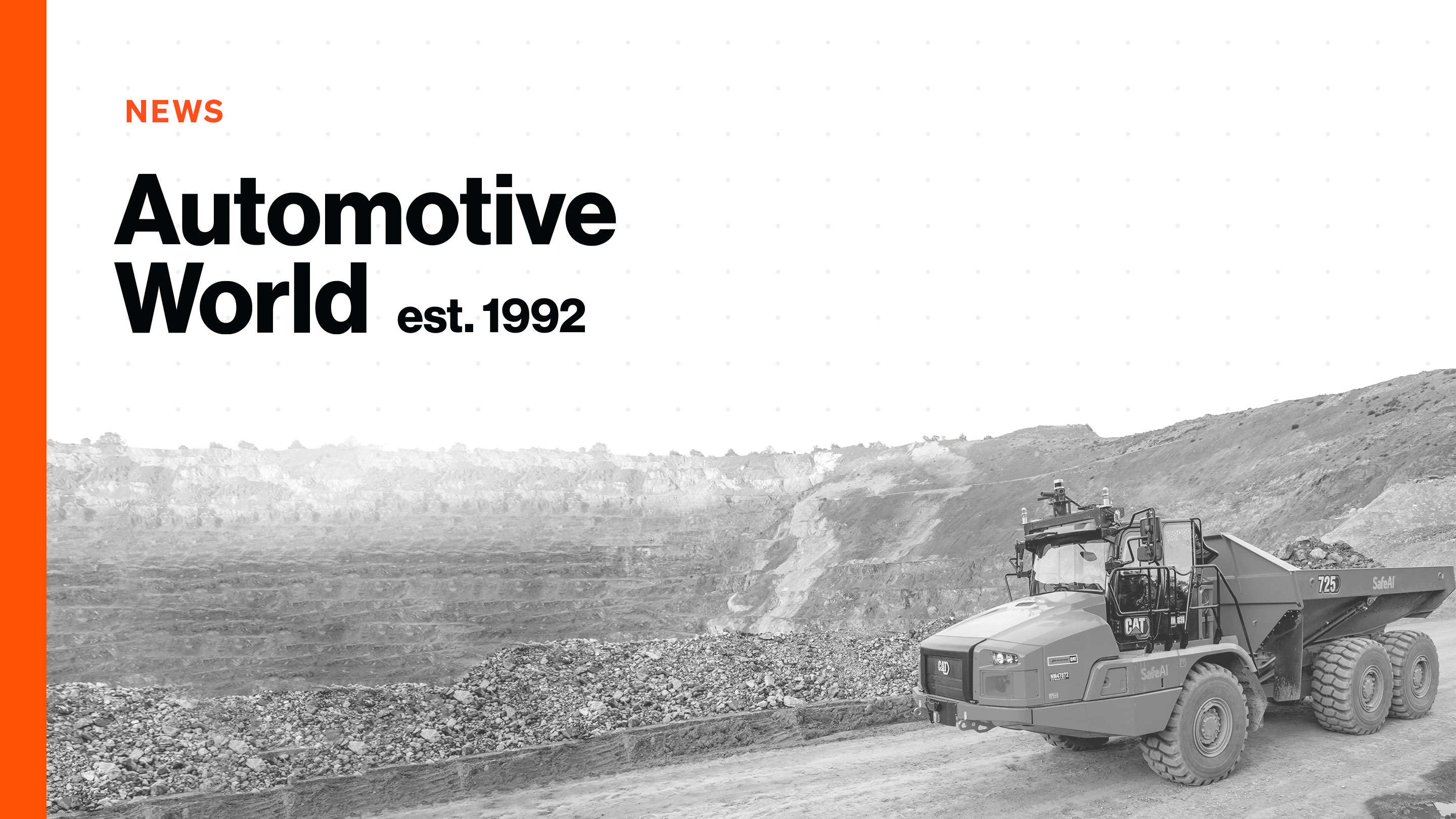

Regarding SafeAI’s autonomous retrofit of mining and construction vehicles—trucks, loaders, and dozers—Halder provides an illustrative example: “One of the retrofit vehicles is the Hitachi EH3500, a US$5m truck the size of a small building. We add cameras and sensors, such as LiDAR and radar, which are incorporated into the software we use for each vehicle on our computer platform.” SafeAI currently has more than 30 software patents filed, with a dozen granted.

Two confirmed AI patents are crucial to the SafeAI platform. One concerns the machine learning manipulation of perception data, and the other harnesses detailed live map information. Once the vehicles are retrofitted, SafeAI trains key mining site staff so they can integrate them into the mining operation. “We use a combination of algorithms within a tight structure, which we explain to the site team.”

The company also carries out a routine four-layer testing process prior to each deployment, which Halder describes as “paramount to us. We test-run vehicles at a site in Cupertino, California, and then run follow-up tests at the customer’s site.” Once retrofitted vehicles are up and running, he claims immediate gains vindicate the switch to autonomous.

Productivity, safety, sustainability

One gain is simple enough—AVs don’t need a break. “Mining runs 24/7, and human operators are limited to 21 hours activity over a full day and legally have to take a break,” Halder says. “AVs run continuously. Plus, they consistently carry out instructions throughout operation, unlike humans, who are naturally more intermittent. So, you get better cycle proficiency and productivity, which amounts to a 25% efficiency increase.”

There’s also the removal of danger to human operators. Data from the International Council on Mining and Metals shows that 44 of its members died while mining in 2020, 45 in 2021, and 33 in 2022. Additionally, SafeAI’s imminent switch from gasoline engines (which average around 40% efficiency) to electric batteries (more than 90%) will further improve performance at a lower long-term cost while drastically cutting emissions. “The Cat 725, a 25-ton truck with an electric battery, will be our first autonomous electric truck,” Halder says. The electric Cat 725 will be unveiled in November 2023.

Halder concedes that the electric mining transition will not be without logistical difficulties. “Going electric adds a layer of difficulty. The battery is not quite therefor every size of vehicle.” In all cases, he suggests that the mining industry will need to amend site infrastructure to charge the vehicles.

SafeAI currently operates solely in Australia, but has plans for global expansion.

SafeAI currently operates solely in Australia, but has plans for global expansion.

Future developments

To drive the growth of autonomous mining vehicles, SafeAI wants to expand globally. It currently operates only in Australia—SafeAI’s first autonomous mining deployment was in partnership with Australian mining company MACA in March 2022. “But we’re discussing expansion into Canada, Brazil, Chile, and the US,” adds Halder. “We’ll expand further once we’ve successfully demonstrated that we can run in those regions.”

AVs consistently carry out instructions throughout operation, unlike humans, who are naturally more intermittent.

An important step will be retrofitting a wider portfolio of mining vehicles. “There are 1.2 million different types of vehicles in mining and construction, and only 1,200 are autonomous,” Halder states. “Every year sees up to around 500 new vehicles join the industry. In five to ten years, we want to make as many of those new vehicles autonomous as we can. In ten years, we want to see 20,000-40,000 AVs.”

If automation continues to improve sustainability and productivity in lithium mining—Halder claims up to a 20% greater yield compared to equivalent human-run operations—as well as eliminating the fear of injuries or fatalities, it could quickly become the industry standard. “All mining CEOs want this tech,” he concludes. “But they want it from a reliable partner as part of a continuous project. For them, it’s about business, not technology. They just want a better, faster solution.”