Nikkei XTech: Obayashi’s US-born “autonomous driving dump” goes to Japan

The two companies are working on autonomous driving of an articulated dump truck (a dump truck with a folding body structure) made by Caterpillar in the United States, with the aim of improving the productivity of construction work and responding to the shortage of heavy equipment operators.

A LiDAR (rider), a camera, a GNSS (general term for satellite positioning system) / IMU (inertial measurement unit) unit that estimates self-position / attitude, and a computer are attached to a dump with a maximum load capacity of about 24 tons, and the control developed by Safe AI Autonomous driving with software. The software was refined by Safe AI by repeating driving simulations on a computer. The strength of the company is that it can be autonomous regardless of the manufacturer or model of the dump truck.

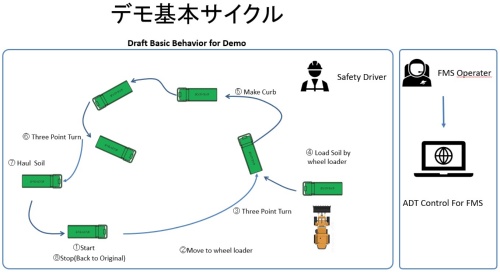

In a demonstration experiment conducted on November 4, 2009 at a quarry in the mountains of Silicon Valley, it was confirmed whether a series of movements from loading and unloading of soil could be autonomous.

In the experiment, after traveling to the loading point of earth and sand, it made a 3-point turn (turning direction) and stopped, and when the loading was completed, it restarted. The cycle of making a 3-point turn again at the unloading point, stopping, unloading the earth and sand at the specified position, and returning to the starting point was carried out three times. Only the wheel loader that loads the earth and sand is operated by a person.

What I checked on the first lap was whether the set route could be driven autonomously as described above. The dump truck went through a series of cycles smoothly without stopping or going off the route. Hiroto Sato, director of the Obayashi Business Innovation Promotion Office, who has been stationed in Silicon Valley and has been working on collaboration, said, “You can quickly decide on a three-point turn.”

Mr. Koji Shiono, Engineering Head (Japan Branch) at Safe AI, said, "The position of the car body can be estimated accurately, the trajectory can be drawn well using advanced algorithms for route planning, and the control algorithm that executes the plan properly. Have these three points. " Ryu Hiratsuka, the representative of SafeAI Japan GK (Tokyo, Chuo), which was established on October 1, 2009, said, "If you are on a straight road, you can drive only 25 cm off the route."

For the estimation of the position, the 3D digital map of the site prepared in advance and the information acquired by GNSS and LiDAR are used. Since the work environment changes daily at the site, the digital map needs to be updated. When implementing, we plan to first measure and create a base map, and then update with the data acquired while the heavy equipment is autonomously driving.